Services

|

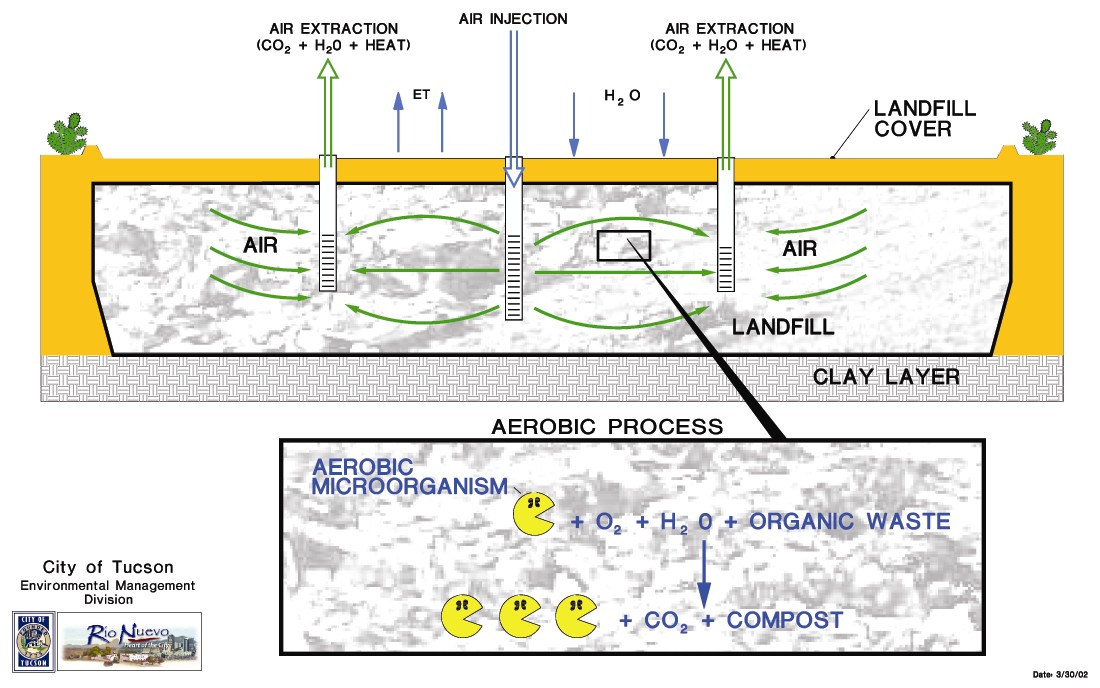

Aerobic and Anaerobic Bioreactor Engineering When it comes to turning a landfill into a bioreactor, HGC provides the technical expertise necessary to properly evaluate, design, construct, and operate a full scale bioreactor system. HGC’s bioreactor experience includes pioneering research into aerobic bioreactors and the engineering skills for conventional bioreactor projects. Aerobic Bioreactors Injecting air and moisture into a landfill converts it to an aerobic bioreactor, and hastens municipal solid waste degradation and land reutilization. Aerobic degradation can achieve degradation rates one to two orders of magnitude above conventional landfill degradation rates. The aerobic process changes the degradation product from methane to carbon dioxide, inhibiting the buildup of explosive landfill gasses. The end product is an inert degraded compost with undegraded metals and plastics. Safe and successful implementation of this innovative process requires managing temperature through control of injected and evolved gases and liquids. HGC has designed, constructed, and operated the aerobic bioreactor pilot system for the Rio Nuevo Land Development Project for the City of Tucson in Tucson, Arizona. We provided technical oversight and management of the Three Rivers Landfill Aerobic Landfill Demonstration Project in South Carolina, and are currently part of a team involved in aerobic and anaerobic bioreactor studies at the Yolo County Bioreactor Project in California. Our past work included preparation of a three-dimensional aerobic-biodegradation, flow and transport model of a landfill; where we simulated the effects of air and water injection on the landfill’s production of gas and heat. As one of the few engineering firms to have worked with aerobic bioreactor technology and with more than 15 years of in-situ pneumatic experience, HGC is eminently qualified to provide these services. HGC holds an exclusive license in Arizona and Florida on aerobic bioreactor patents. Anaerobic Bioreactors

The financial success of an LFG-to-energy project can hinge on improving

LFG measurement and collection or enhancing the landfill’s

LFG production. Raising the landfill’s moisture content increases

methane production but requires careful monitoring and management

to control leachate. We have the gas-and-liquid flow and landfill

experience to address these problems, and have developed the measurement

and simulation tools necessary to safely enhance anaerobic LFG production

in bioreactor landfills. HYDRO GEO CHEM, INC.

|