Services

|

The

answer to this may seem obvious - if you’re talking about the physical

description of a tank. However, there are regulatory definitions that

dictate if your tank is an above-ground tank or a stringently regulated

underground storage tank (UST). According to 40 Code of Federal Regulations

(CFR) Part 280, an above-ground tank is regulated the same as an UST

if 10% or more of the total system volume is beneath the ground surface.

This includes piping and delivery connections. In fact, all regulated

above-ground tanks and USTs are referred to in the regulations simply

as “tanks”.

The regulatory requirements of RCRA Subtitle I, which covers the management of USTs, include construction and notification procedures; technical operating standards; leak detection, reporting, and corrective actions; and stringent tank closure guidelines. These regulations were enacted in 1988 with provisional exceptions for pre-existing tanks. But beware - the grace period for tanks existing prior to 1988 will end in two years. By 1998, all tanks must conform to spill, overfill, and corrosion protection standards. The Office of Underground Storage Tanks, within the Office of Solid Waste and Emergency Response of the US Environmental Protection Agency (EPA), has published a document about this deadline and the actions that must be taken. “Don’t Wait for ’98" will help you understand your responsibilities as the owner of a previously non-regulated tank and can be obtained without charge by calling the EPA’s UST Hotline at (800) 424-9346. There are many exceptions in the definitions of regulated tanks. For example, if your tank only stores heating oil which is used on the premises, it is not regulated. Get to know RCRA Subtitle I; check out 40 CFR Part 280.10. Otherwise, the tank you thought was above the ground, and the law, might not be. Doyne Wrealli, CHMM Environmental Manager

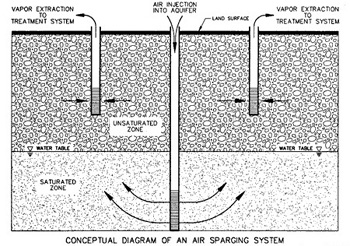

Air

sparging is the process of injecting air below the water table to

remove organic compounds by volatilization or aerobic biodegradation.

Sparging systems are typically designed on the basis of pilot tests.

The primary goal of the pilot test is to estimate the extent of the

effective air sparging zone that can be expected to develop around

a typical well at a particular site.

The

effective air sparging zone can also be evaluated using an appropriate

computer model of multi-phase flow and contaminant transport. The

computer model can provide important insight into the factors affecting

air sparging at a site. The model also allows efficient evaluation

of alternative system designs. The

effective air sparging zone can also be evaluated using an appropriate

computer model of multi-phase flow and contaminant transport. The

computer model can provide important insight into the factors affecting

air sparging at a site. The model also allows efficient evaluation

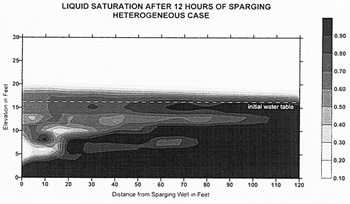

of alternative system designs. Hydro Geo Chem recently presented the results of an evaluation of the effect of constant and variable air-injection rates on the effective sparging zone in both homogeneous and heterogeneous aquifers. The effective air sparging zone, defined as the unsaturated volume of porous medium resulting from the sparging process, displays characteristic temporal patterns of expansion, collapse, and stability in a homogeneous aquifer with a constant air injection rate. Because of the collapse, the effective sparging zone under continuous, long-term operation was found to be only ½ the total volume of the zone developed during the initial stage of operation. Similar temporal patterns were observed at constant injection rates into a heterogeneous aquifer, although the patterns were more complex. Deep higher-permeability channels that are initially treated by the sparging process were found to collapse unless flows were increased. Furthermore, in both homogeneous and heterogeneous aquifers, the air pressure measured at the sparging well stabilized at about the time of maximum extension, remaining nearly constant through the collapse and stability phases. Cyclic variation of flow in the heterogeneous medium produced a seemingly chaotic pattern of air circulation for the first few hours with unsaturated channels forming, resaturating, then re-forming through the aquifer. The sparging zone eventually collapsed unless peak flows were constantly increased. Increasing air injection rates was found to be the only way to continue to move air through the deeper channels. The results of the simulations have important implications regarding sparging system remedial design. These are: 1) the volume of porous media affected by the sparging process is reduced with time unless flows are increased,

Stewart

J. Smith

Many of the speakers described Washington D.C.’s political climate and economic forecasts for water rights settlements. Future settlements will likely not include funding for major irrigation projects which are the standard for quantifying Indian water rights. Rather, settlements will probably include some provision for limited water marketing to help reduce federal costs. Both House and Senate versions of the federal budget cuts call for reductions in money available for settlement and litigation for fiscal year 1996. Matthew

P. Wickham How

has your company recorded the financial liability for environmental

clean up? The Accounting Standards Executive Committee recently issued

a draft document for public comment (Exposure Draft) of a proposed

set of rules on this subject entitled, “Environmental Remediation

Liabilities.” In 1992, Price Waterhouse completed a survey which indicated

that 62% of the respondents had known environmental liabilities that

had not yet been recognized in the respondents’ financial statements.

The purpose of the Exposure Draft is to provide guidance for measuring

the amount of and determining the timing for recording the environmental

liability. Current

accounting rules require that companies record a liability when it

is both probable that an asset has been impaired or a liability has

been incurred and the amount of the loss can be reasonably estimated.

Environmental

liabilities generally arise within a legal framework. If litigation,

a claim, or an assessment has been asserted or is probable of assertion

and if your company is associated with the site, the company must

assume that the outcome of such litigation, claim, or assessment will

be unfavorable. Therefore, a liability has been incurred. What

if you believe that the total cost of your clean up cannot be reasonably

estimated? In general, the accounting rules state that when you can

estimate a range of loss, then you must record it. This Exposure Draft

further stipulates that the overall recorded liability may be based

on a composite of cost ranges for some components of the liability

and best estimates within cost ranges of other components of the liability.

The

Exposure Draft identifies six benchmarks in the financial recognition

process and the liability should be evaluated as each of these benchmarks

occurs:

Michelle Quintanilla, CPAChief Financial Officer Return to top of page.

HYDRO GEO CHEM, INC.

|

The

simulations also suggest that cyclic injection of air may result

in a relatively stable sparging zone that is nearly identical to

that developed by constant injection of twice the volume of air.

A manuscript describing the sparging evaluation may be obtained

by contacting Hydro Geo Chem, Inc.

The

simulations also suggest that cyclic injection of air may result

in a relatively stable sparging zone that is nearly identical to

that developed by constant injection of twice the volume of air.

A manuscript describing the sparging evaluation may be obtained

by contacting Hydro Geo Chem, Inc.  The

Fourth Symposium on the Settlement of Indian Reserved Water Rights

Claims was held in September in Portland, Oregon. The symposium

provided information on the negotiation process and included discussions

of the status of negotiated Indian water rights settlements in the

west and water marketing provisions in settlements. The symposium

was sponsored by the Native American Rights Fund and the Western

States Water Council.

The

Fourth Symposium on the Settlement of Indian Reserved Water Rights

Claims was held in September in Portland, Oregon. The symposium

provided information on the negotiation process and included discussions

of the status of negotiated Indian water rights settlements in the

west and water marketing provisions in settlements. The symposium

was sponsored by the Native American Rights Fund and the Western

States Water Council.